Surface triple junction matters in nanocrystal deformation

The high strength of nanostructured materials is usually attributed the size effect, i.e., the material becomes stronger as grain size and/or material thickness decreases to nanometer scale. The mechanism of such “smaller is stronger” effects has been extensively studied in previous studies, with focus on the roles of plane defects (such as grain boundary, phase boundary and surface) in deformation. The contribution of triple junctions to nanomaterial’s strength has been largely overlooked because the fraction of atoms residing at triple junctions are rather small and it is difficult to decouple triple junction effect from the contributions of grain boundary and other planar defects.

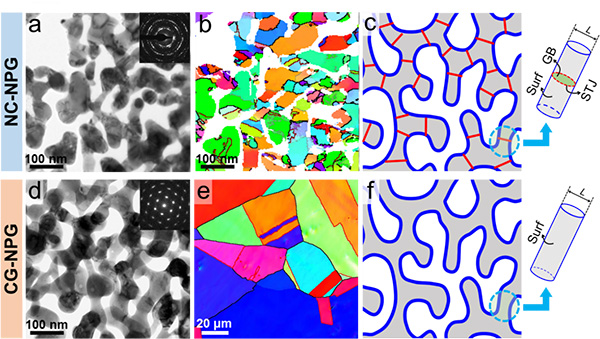

Recently, a team at SYNL led by Prof. Hai-Jun Jin decoupled the effect of surface triple junctions (STJs) on strength from other effects by a comparative study between the compression behaviors of coarse-grained and nanocrystalline nanoporous gold samples, while their surface state was modified electrochemically. As a specific type of triple junctions, STJs are the termination lines of grain boundaries at solid surface. The new results suggest that STJs emerge as an important even decisive parameter controlling the plastic deformation and strength of polycrystalline materials, when they are shrunk to below 100 nm.

The new findings suggest that the structure and chemistry at surface triple junctions should be considered in understanding and tailoring the mechanical response of sub-100 nm scale materials, such as the thin films and nanowires that are widely used in modern industry. In a more general sense, other type of triple junctions, including the grain-boundary triple junctions in nanocrystalline materials, may also play critical roles in plastic deformation at a length scale much larger than previously thought, and deserve more attention in the development of high-strength nanomaterials.

The paper entitled "Surface triple junctions govern the strength of a nanoscale solid" was published in Physical Review Letters (https://journals.aps.org/prl/abstract/10.1103/PhysRevLett.126.235501). This work was highlighted in PRL Editors’ Focus and featured in Physics.

Figure 1. NPG with high-population STJs. a) TEM image and an inset selected area electron diffraction (SAED) pattern, b) PED orientation map, and c) a schematic illustration of NC-NPG structure. d) TEM image and an inset SAED pattern, e) EBSD orientation map, and f) a schematic illustration of the structure of CG-NPG. Surf: solid surface. GB: grain boundary. STJ: surface triple junction.

Figure 2. In situ compression of NPG in an electrochemical environment. a) Schematic illustration of an electrochemical cell for in situ compression. b) Compressive engineering stress-strain curves of a typical NC-NPG (L = 43 nm) measured in situ under electrochemical control. c) Δσ/σCLN, plotted as a function of ligament size L, for CG-NPG and NC-NPGs. Inset table shows major defects and their sensitivity to electrochemical modifications (on/off: sensitive; off: insensitive; –: this defect is very few or does not exist).