Very High Cycle Fatigue Fracture Mechanism of Rare Earth Bearing Steel

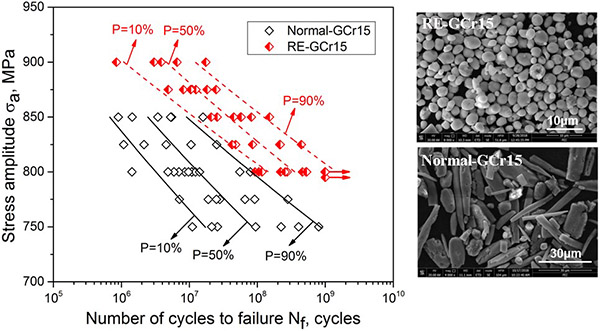

Bearing is the core part of mechanical equipment, and its primary failure form comes from contact fatigue failure. Because the fatigue failure of bearing mainly originates from non-metallic inclusions, the optimal control of non-metallic inclusions in bearing steel is of great importance. Advanced steel materials division has independently developed the preparation technology of high-purity rare earth (RE) metal and ultra-clean RE-treated bearing steel, and made the corresponding production process specification. It strikingly breaks through the traditional technical bottlenecks of nozzle clogging and performance fluctuation existed in previous rare earth steel. The inclusions in RE bearing steel have been significantly improved and the stable industrial production of high-quality RE bearing steel has been realized. RE treatment can modify large inclusions in bearing steel into small RE inclusions, thereby improving the fatigue property of bearing steel with very high cycle tension-compression fatigue life prolonged by more than 10 times. Further studies indicate that cellular substructure and microcracks form easily in the matrix structure surrounding common aluminum oxide inclusions under the fatigue loading, while RE inclusions with low hardness and brittleness can coordinate the deformation of the matrix, consequently alleviating the stress concentration at the interface between the inclusions and the matrix and delaying the evolution of dislocation substructure in the matrix and the initiation of microcracks. In addition, the coordinated deformation of small RE inclusions reduces the driving force of crack propagation, so the dislocation evolution in the martensite matrix and the formation of crack propagation channel proceed slowly. Under such circumstance, the fine granular area (FGA) gets fully developed, which inhibits crack propagation and prolongs fatigue life. The above studies clarify the very high cycle fatigue fracture behavior of RE bearing steel and the mechanism of its superior fatigue property from the perspective of microstructure evolution and FGA formation.

Fig. 1.P-S-N curves and inclusion modification inRE-GCr15 and Normal-GCr15 bearing steels